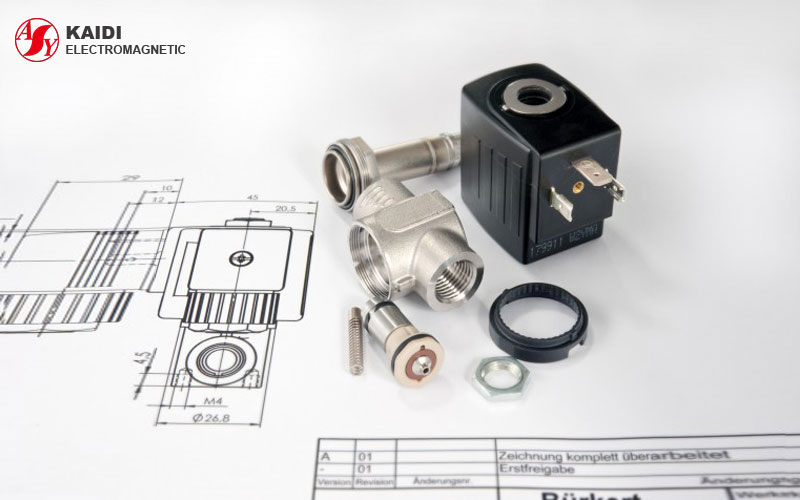

Solenoid valve becomes the important element of complete equipment and household electric appliance. The solenoid valve develops into a series of electrical products. According to the power system, solenoid valve can be divided into AC solenoid valve, DC solenoid valve, latching solenoid valve; according to the applications, there are pneumatic solenoid valve and solenoid valve for flow control, solenoid valve for refrigeration equipment, steam solenoid valve, pulse-solenoid valve; according to the environment, there are general type, outdoor type, and explosion proof solenoid valve. This article gives a solution on how to design solenoid coil quickly? Solenoid coil plays a core role in the solenoid valve, basically, quality solenoid coil decides the quality of solenoid valve. Specific steps of designing solenoid coil as below.

Confirm design requirements

Based on meeting two main properties, also with no changes in core diameter, shading coil size, core stroke, just design turns per coil and wire diameter. Under the rated working voltage, original coil former, we need to confirm the main properties the solenoid coil should reach.

Design and calculation

Turns per coil calculation

Solenoid coil calculation: when the current through solenoid coil changes, for electromagnetic force remain at the same, ampere-turns (IW) should be fixed so that turns per coil is:

W2 = W1×I1/I2

Current density calculation

Select existing two solenoid coils that reach the requirements mostly. For example, there is an AC 220V solenoid coil, loading DC current and measure its minimum voltage, load 1.1 times rated voltage and measure the temperature rise, the differences between minimum operating voltage and the designed minimum operation voltage is properly lea than 30%, its temperature rise is less than 30% compared to designed one. The current density calculation formulates as follows:

IJ = I/πr2

r: current lead radius; I: working current with the rated voltage.

DC solenoid force calculation

F = 62.8 × (IW)2 [πr2/δ2 + g/μo(z/lc)2] × 10-8[2]

According to the design requirement, we can get that the value in the bracket is a constant, so we set it as k, the final formulate shown below:

F = k (IW)2

From above formulate, we can know that remain the solenoid coil at same requires maintain the value of IW.

- If the minimum working voltage of two selected coils are both less than design requirement, temperature rise is also less than design requirement, we choose existing solenoid coil;

- If the minimum working voltage of two selected coils are both bigger than design requirement, the temperature rise is also bigger than design requirement, so the designed solenoid coil should increase wire diameter value and decrease turns per coil;

- If the minimum working voltage of one selected coil is less than design requirement, the temperature rise is bigger than design requirement, and another coil is opposite, the wire diameter should use the value between wire diameter values of two selected coil; turns per coil use the same way to decide.

Main properties test of product

By the practical need of solenoid coil design, for testing the parameter design of solenoid coil, it’s necessary to make some tests for main properties. After the main properties reach the requirement and make every property of coil by the industrial standard.

Conclusion

Through the design we made above, we get a quick method to design solenoid coil. The new type of solenoid coil design has features like quick and convenient, high reliability. This new design of solenoid coil not only mostly shorter the time from design to production, but also decrease the cost of product tests. From the result of the test, we can make sure that new design meets the requirement of quick design and parameter.

Kaidi specializes in manufacturing solenoid coil over 40 years. We have produced technology and advanced production equipment. Rexroth, Yuken and Vickers solenoids are our popular products. Besides, we also provide custom solenoid according to clients’ needs.