The process control system can be divided into two categories according to the type of actuator: continuous control system and switch control system. The actuators of the continuous control system are mainly pneumatic regulating valve and electric regulating valve. The actuator of the switch control system is solenoid valve. In general, solenoid valves can only be used for switch control. But if the parameters require continuous control, we should adopt the pneumatic or electric control valve. However, with the advent of the proportional solenoid valve, this perception has been changed.

In the past, the control component of the hydraulic control system is mainly servo valve, but the structure of the servo valve is complex and the price is expensive. After the proportional solenoid and proportional solenoid valve appearing in the market, they became a new choice for some control systems. The control system which composed of the proportional solenoid valve and the actuator has the advantages of low cost and simple structure. At present, it is widely used in the hydraulic control system.

Principles of the Proportional Solenoid and Proportional Solenoid Valve

The on-off solenoid and the proportional solenoid work in much the same way. When the solenoid coil is electrified, the yoke iron and armature will produce magnetic flux and electromagnetic suction internally, then the armature will be sucked towards the yoke iron and the spring on the armature will be compressed. When the electromagnetic force and spring force balance on the armature, the armature will stop its displacement.

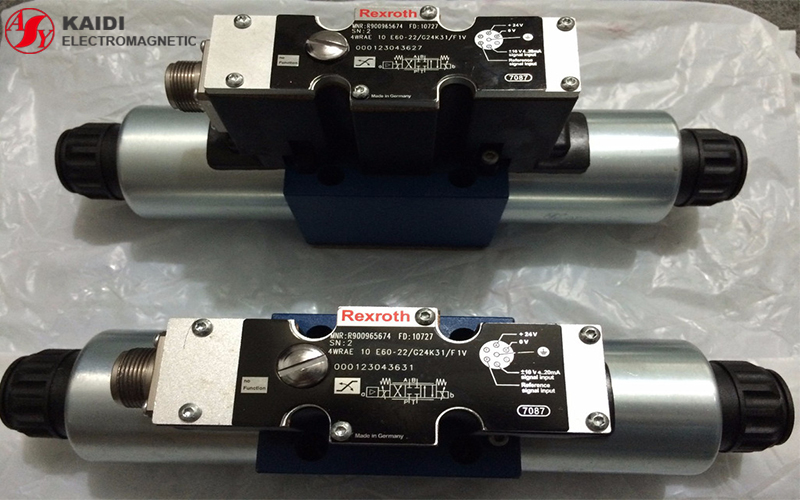

At present, the proportional solenoid valves used in the process control system are all single level valves, which is not much different from ordinary single-level solenoid valves. As shown in the figure below, the springs they used are generally helical compression springs, but some of the smaller proportional solenoid valves will adopt leaf springs.

Single Stage Proportional Solenoid Valve

After the control signal enters the controller and be amplified, add a certain voltage at both ends of the proportional solenoid coil, then the control signal will be converted into a current signal, driving armature (i.e., valve core) to open. And after the electromagnetic force and spring force balance on the spool, the opening of the valve will remain unchanged. However, if the input-signal changes, the valve opening will also change, so as to control the required parameters.

Features of the Proportional Solenoid Valve Control System

The proportional solenoid valve control system generally has the following functions:

- Temperature compensation function: the circuit inside the controller can automatically compensate the current change caused by the solenoid valve heating.

- Switch start time ramp function: the start time of switch can be adjusted to prevent water hammer phenomenon.

- Small signal shutoff function: when the input signal is less than a certain critical value, the valve will be closed automatically.

- Extremum setting function: the maximum and minimum values of the coil current can be set so as to determine the extremum of the control system.

- Remote control function: the remote signal can be 1~5 VDC, 4~20 mA or other standard signals.

- Field parameter setting function: the control parameters of the intelligent cartridge controller can be set on site.

- Safety function: after the power is cut off, the valve will be automatically closed.

Advantages and Disadvantages of the Proportional Solenoid Valve Control System

The traditional continuous process control system has many accessories, and its cost and failure rate is high. While the proportional solenoid valve, which coupled with intelligent cartridge controller and sensors, can constitute a precisely controlled proportional control system, which costs only about 1/3 to 1/5 of the traditional control scheme. It can not only be used for the open-loop system but also the closed-loop system.

Due to the limited output power of the solenoid, the caliber of the proportional solenoid valve is limited to 1215~50 mm, and the pressure is within the range of vacuum -1.0 MPa. However, the traditional pneumatic and electric control valves have a larger caliber. They can withstand higher pressure and have better control performance.

The Application of the Proportional Solenoid Valve Control System

After the improvement of proportional solenoid technology, proportional solenoid valve technology and intelligent cartridge controller technology, the proportional solenoid valve control system has expanded from hydraulic industry to process industry, household appliances industry, automobile industry and some other industries. In the process industry, the proportional solenoid valve control system can be used for flow control, liquid level control, temperature control and pressure control. In addition, it can also be used in many industries, such as water treatment, chemical process, semi-conductor industry, food and beverage industry and pharmaceutical industry. We believed that with the popularization of proportional solenoid valve control system and technical progress, more and more applications will be made in the future.