Solenoid has many different meanings in different areas. For example, for physics research, solenoid means a coil wrapped around a round metal, and after the coil has been electrified, it will produce a magnetic field. There are many types of electromagnets in physics area, not every electromagnet can be called as solenoid, it has specific naming rules based on their functions, some may be called solenoid, some are inductors or even electromagnets, etc. For engineering industry, solenoid means a series of transducers, when the solenoid has been electrified, it can convert the electricity into mechanical movement. The same as solenoid in physics area, solenoids with different functions also have different names. The name “solenoid” mainly refers to solenoid that used as an actuator of pneumatic valves and hydraulic valves. Solenoid switch refers to the solenoid that used on electrical switches.

What is Solenoid Coil?

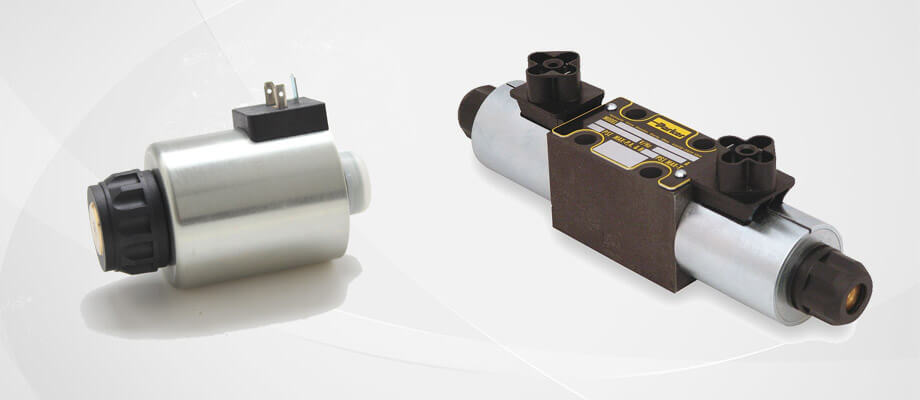

Solenoid is consist of solenoid coil and tubes. The solenoid coil is consist of a conductive core which has a hollow center, and a piece of copper wire wound around the hollow core. When the solenoid has been electrified, a current will pass the solenoid coil, and create a magnetic field. For the major solenoid functions, the magnetic field will provide some magnetic potential that can convert the magnetic force into some sort of mechanical movement. Take hydraulic solenoid as an example, the magnetic force will drive the movement of metal core, therefore, the movement of the plunger can trigger the hydraulic valve.

The Relation Between Solenoid Coil & Tube

In a complete solenoid, both the solenoid coil and tube are the most important parts. Solenoid coil and tubes have different functions, and together, the two parts trigger the valve to operate. When the electricity passes the solenoid coil, the plunger in solenoid tube will move, which actuate the valve to change the directions of fluids, or the pressure of the valve.

When solenoid coil has been electrified, the valve turns on, and when we turn off the power of solenoid coil, the valve turns off, too. The plunger in solenoid tube is the final parts that turn on and off the valves. Therefore, to operate the solenoid successfully, need both of the solenoid coil and tube work precisely. If anyone goes wrong, the complete valve is not able to work. Generally speaking, solenoid coil is the most trouble one, the most frequent problem is the burnt out of solenoid coil. You can use different way to fix the solenoid coil and tubes based on different problems. But in real practice, when the solenoid coil goes wrong, some people will replace the solenoid coil to make the valve better operated.

The structure of solenoid valve is simple, and the working pressure difference of solenoid valve is small, therefore, solenoid coil may have voltage surge caused by the speed of the switching of on-off function, this is also the main reason which causes the burnt out problem of solenoid coils.

How to Install A Solenoid Coil?

When you try to install a hydraulic valve, there are some tips about solenoid coil you have to pay attention to:

- Check whether the parameters of solenoid valve and solenoid coil are fit. Like the pressure difference, if the pressure difference of solenoid valve and coils are different, solenoid coils are easily burnt out. The fluctuation of voltage must stay in a standard range according to the rated voltage.

- Before the solenoid valve has been placed in the pipeline, the pipeline must be cleaned. If there are residues in pipeline, it may affect the working performance of solenoid valve. To prevent such circumstances, you can install a filter screen in the pipeline.

- Solenoid coils must be installed vertically on the pipeline. If the solenoid coil cannot be placed vertically, you must pre-order the suitable solenoid valves, otherwise, the solenoid valve cannot work as normal.

- When you install a complete solenoid valve, there should be an extra security process, a manual shut off valve. Therefore, if there is anything goes wrong, it can stop the valve immediately, and fix the problem in short time.

- When you install the solenoid coil, you must pay attention to the directions, it can not be placed reversely. You must follow the instruction to install the solenoid coil, otherwise, the complete solenoid valve can go wrong.

- If the media you use may have water hammer phenomenon, you must take relevant safety measures or choose the solenoid valves that have water hammer preventing function.

- The solenoid coil cannot be continued electrified, it can reduce the serve life of solenoid coil, and even the complete solenoid valve.