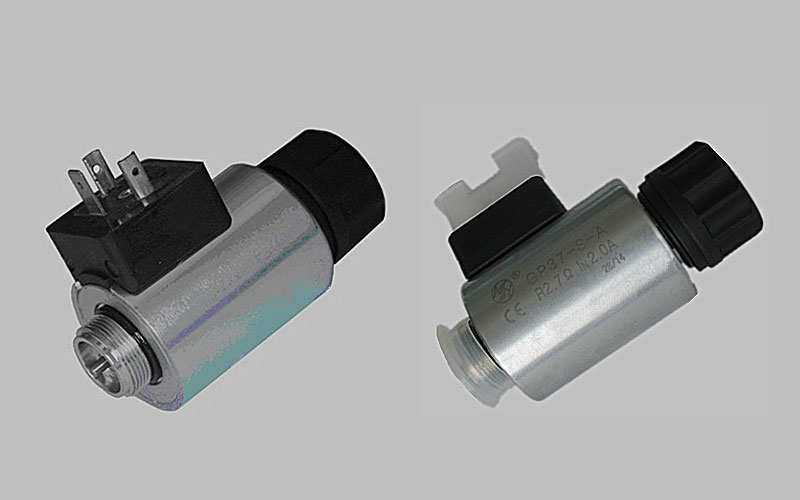

Proportional solenoid is an important electro-mechanical converter

An electro-mechanical converter is one of the key components of an electro-hydraulic proportional valve. Its function is to convert the amplified input signal current into a mechanical quantity proportionally. The proportional solenoid is one of the most important ones.

The function of the proportional solenoid is to convert the electric signal of proportional control amplifier into force or displacement. The proportional solenoid has a large thrust and a simple structure. It has low requirements on oil cleanliness, convenient maintenance and low cost. It is an electro-mechanical conversion device widely used in electro-hydraulic proportional control components. The characteristics and working reliability of proportional solenoids have an important influence on the performance of electro-hydraulic proportional control system and components.

Proportional solenoids are widely used in some applications of electro-hydraulic proportional control technology due to their importance. For example, the application of proportional solenoids in the hydraulic test machine of steel tube, the application of proportional solenoids in the electro-hydraulic proportional control system of aircraft blocking technology, the application of proportional solenoids in the hydraulic system of die casting machine and so on.

Classification of Proportional Solenoids

Proportional solenoid types according to the working principle can be divided into the following categories.

- The force control type

This kind of solenoid has short travel, and the output force is proportional to the input current. It is often used in pilot control stage of the proportional valve. - Stroke control type

This type of solenoid consists of a control solenoid and a load spring. Solenoid valve output force first through the spring into the output displacement, the output displacement is proportional to the input current. Its working stroke is up to 3mm, with good linearity can be used in direct proportional valve. - Position adjusted type

The position of the armature is detected by the sensor, a feedback signal is sent out in the valve, and the position of the armature is adjusted after comparison in the valve. Closed-loop control of stroke in the valve has high accuracy, and the position of armature is independent of force.

| Code | GH263-035 | GH263-045 | GH263-060 |

|---|---|---|---|

| Rated Current(A) | 0.68 | 0.8 | 1.11 |

| Room Temperature Resistance(Ω) | 24.6 | 19.5 | 16.7 |

| Rated Force(N) | 50 | 75 | 145 |

| Rated Stroke(mm) | 2 | 3 | 4 |

| Total Stroke(mm) | 2.5 | 6 | 8 |

| Force Lag Characteristic(%) | ≤3 | ≤3 | ≤4 |

| Current Lag Characteristic(%) | ≤3 | ≤3 | ≤4 |

| Repeat Accuracy(%) | ≤1 | ≤1 | ≤1 |

| Static Oil Pressure(MPa) | 21 | 21 | 21 |

| Degree Of Enclosure | IP65 | IP65 | IP65 |

The Performance Requirement of Proportional Solenoids

- The proportional solenoids should have a horizontal suction characteristic, that is, the mechanical force of the output is proportional to the size of the electrical signal, independent of the armature displacement. It can convert electrical signals to mechanical forces continuously in proportion to output to hydraulic valves.

- It has enough output force and stroke, compact structure and small size.

- Good linearity, small dead zone and high sensitivity.

- Good dynamic performance and fast response.

- The temperature rise of the proportional valve shall not exceed the maximum temperature control value in long-term operation.

- It can withstand the high pressure of the hydraulic system and has good anti-interference.