Hydraulic directional valve is a type of hydraulic actuators used to control the directions of hydraulic fluids. There are many different types of hydraulic directional valves with different controlling methods.

Solenoid Operated Directional Valve

Solenoid operated directional valve is the most widely applied directional valves. The working positions of solenoid operated direction valve is changed by the hydraulic solenoid force. The force of hydraulic solenoids will push the valve spool to realized the redirection of the directional valve. Solenoid operated directional valves can be controlled by the signals released by button switch, journey switch, limit switch, pressure switch, etc. Therefore, solenoid operated directional valves are highly automatic components which are easy to operate.

Working Principle of Solenoid Operated Directional Valve

There are many different types of solenoid operated directional valves, but their working principles are basically the same.

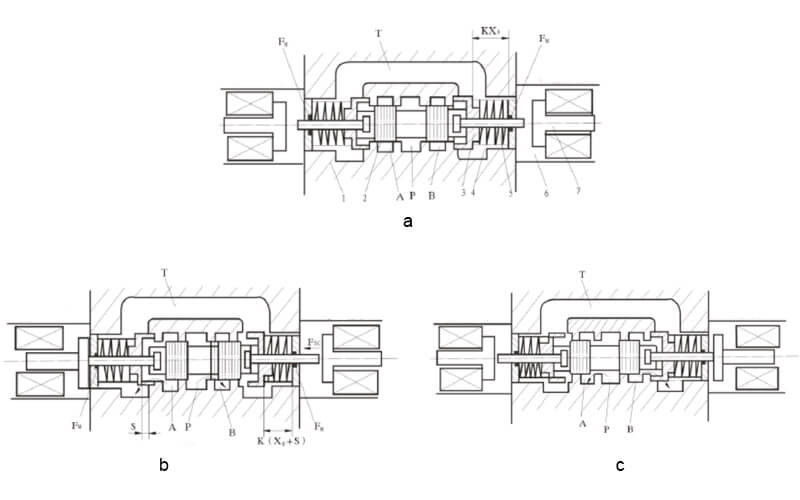

As shown in the figure, there are three ring type undercutting grooves in valve body 1. In the middle of the valve body is the fuel inlet chamber P, at both the two sides of the fuel inlet chamber are the working fuel chambers A and B. Also, there is the oil return chamber T that connected the two sides of the two working fuel chambers.

Also, you can find the spring seat 3, reset spring 4, and the push rod 5. Last but not least, two on-off solenoids have been placed on the two sides of the valve body.

When both of the two on-off solenoids cut off, the valve spool stays in the middle position (as shown in figure a), and all the fuel chambers P, A, B, T are not connected.

When the left on-off solenoid has been electrified (as shown in figure b), the solenoid force will push the valve spool move right, and the fuel chamber P is connected with chamber B, and fuel chamber A is connected with chamber T.

When the right on-off solenoid has been electrified (as shown in figure c), the solenoid force will push the valve spool move left, and the fuel chamber P is connected with chamber A, and fuel chamber B is connected with chamber T.

Hydraulic Solenoid Types To Trigger Solenoid Operated Directional Valves

There are many different types of hydraulic solenoids used for different solenoid operated directional valves.

AC Solenoids & DC Solenoids

According to different power supply systems, hydraulic solenoids for directional valve can be divided into AC solenoids and DC solenoids. AC solenoids have large starting force, short direction shifting time. But the impact force of direction shifting is large, so the working temperature increases fast, which makes it easy to burn out. On the contrary, DC solenoids have a small volume and little impact force of direction shifting, which makes it has the longer service life.

Dry Type Solenoids & Oil-immersed Solenoids & Wet Type Solenoids

Both AC solenoids and DC solenoids can be made as dry type solenoids, oil-immersed solenoids, and wet type solenoids.

Dry type solenoids have seal rings on the outer circle of the push rod, and the solenoid coil and iron core will not in touch with the hydraulic fluids. For oil-immersed solenoids, there are also seal rings on the push rod, but the solenoid coil and iron core of oil-immersed solenoids are soaked in the pressureless hydraulic fluids. The difference between oil-immersed solenoid and wet type solenoid is that there are no seal rings on wet type solenoids. Wet type solenoid coils can be soaked in hydraulic fluids, which makes it has better heat dissipation efficiency and little frictional force. Wet type solenoids hold the advantages of little noise, long service life and low-temperature rise, which makes it the most widely applied hydraulic solenoid in the market.

Manual Operated Directional Valve

There are two types of manual operated directional valves, spring reset type directional valves, and steel ball orientation type directional valve. For steel ball orientation type directional valve, there are three different working positions for the hand lever. When you push the hand lever, it will cause the relative movement between valve spool and valve body, and the steel balls will help stick the valve spool at the three working positions. For spring reset type directional valves, when you use the hand lever to push the valve spool, you must hold the hand lever at the position, if you release the hand lever, the valve spool will rebound to the middle position under the effect of the spring force.

Recently, there is a new type of manual operated directional valve, rotary mobile directional valve. It adopts a rotation handle that will change the working position of the valve spool via the screw. The rotary mobile type directional valve holds the advantages of small volume, easy adjustment, etc. Moreover, the rotary mobile type directional valve has a lock on the hand lever. If the lock is locked, the hand lever can not be adjusted, therefore, it is much safer than other manual operated directional valves.

Mechanical Operated Directional Valve

Mechanical operated directional valve is also called as cam valve. This is because the direction shift of mechanical operated directional valve is realized by the locating iron or cam. The cam will push the valve spool to trigger the redirection of the valve.