Directional control valve is used to control actuator’s direction, start and stop. Hydraulic directional control valve is a common directional control valve that use hydraulic pressure to control flow direction. To be specific, valve element controls the movement of valve to close flow or change its direction. So that hydraulic valve can start, stop or change the movement. According to the path numbers of directional control valve, we can classify hydraulic directional valve into two-way, three-way, four-way and five-way type.

Directional control valve have a variety of classifications by the movement of valve element relative to valve, handle method, operation, path number, etc. Here are some typical directional control valves divided by handle method, which summarized by KaiDi, a hydraulic solenoid supplier with 70 years’ experience.

Solenoid Operated Directional Control Valve

Solenoid operated directional control valve use hydraulic solenoid to create electromagnetic field, which controls the movement of valve. It basically consists of valve, hydraulic solenoid (solenoid coil and iron core). Obviously, solenoid directional control valve is powered by electric, so it can be divided into AC solenoid and DC solenoid. There are some differences between AC and DC solenoid.

AC solenoid

AC solenoid has the characters of easy operation, big start-up force, big direction change impact, large noise, low reversal frequency (about 30t/min), solenoid coil is easy to be burned-out under low voltage or valve sticking.

DC solenoid

Compared to AC solenoid, DC solenoid has less direction change impact, higher reversal frequency. Due to the characteristic of continuous current, solenoid coil is not easy to be burning-out. DC solenoid is reliable, but it has complex structure.

As the key part of solenoid operated directional control valve, quality of solenoid determine the performance of valve. How to choose high-quality solenoid? More details at solenoid buying guide.

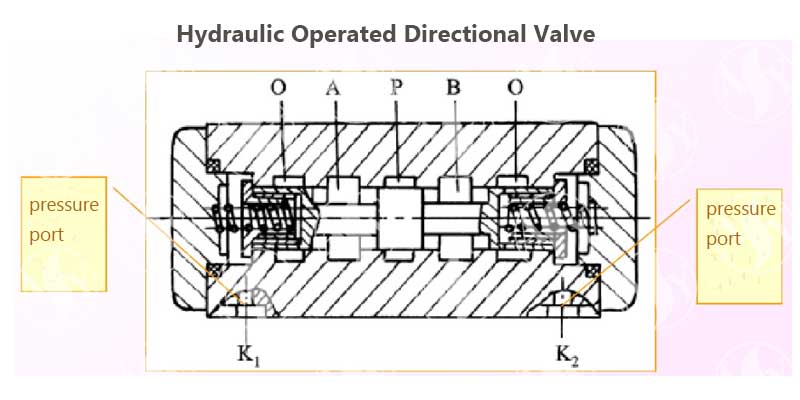

Hydraulic Operated Directional Valve

Hydraulic operated directional valve is powered by fluid pressure. In theory, the valve core of hydraulic operated directional control valve is pushed by the external control pressure, thus changing the flow direction of the hydraulic system. To control the movement speed of valve core, it normally install orifice check unit on the hydraulic control pressure port, also called damper regulator. Hydraulic operated directional control valve has wide applications. It is generally applied in the die-casting machine, press, injection molding machine and so on.

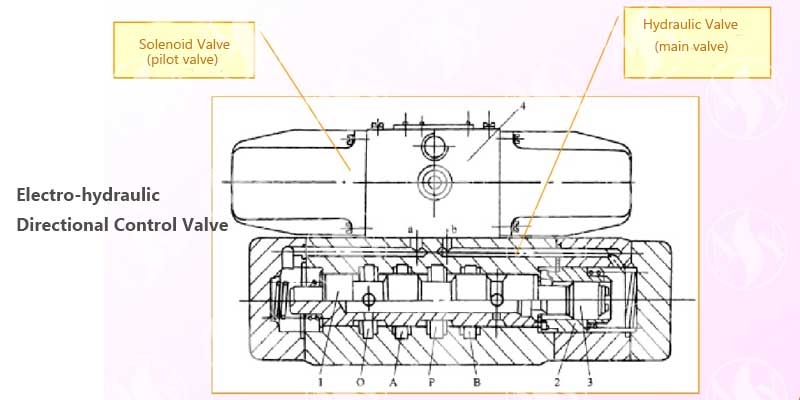

Electro-hydraulic Directional Control Valve

Electro-hydraulic directional control valve is a combination of solenoid operated directional valve (pilot valve) and hydraulic operated directional control valve (main valve). So that, Electro-hydraulic directional control valve has advantage of using low power solenoid control high power main valve. Oil resource and oil return of solenoid operated directional control valve can be set individually, or share with main flow.

Mechanically-operated Directional Control Valve

Mechanically-operated directional control valve is also known as stroke valve. It makes valve core move by means of the iron block and cam installed on the workbench, which control the direction of flow. Technologically, mechanically-operated directional control valve gets commutating speed and reduces reversing impact by changing shape of cam. The structure of mechanically operated directional control valve is easy. Mechanically-operated directional control valve have advantages of reversing smoothness, reliability and position precision high. In general, it can be used to control the stroke of moving parts.

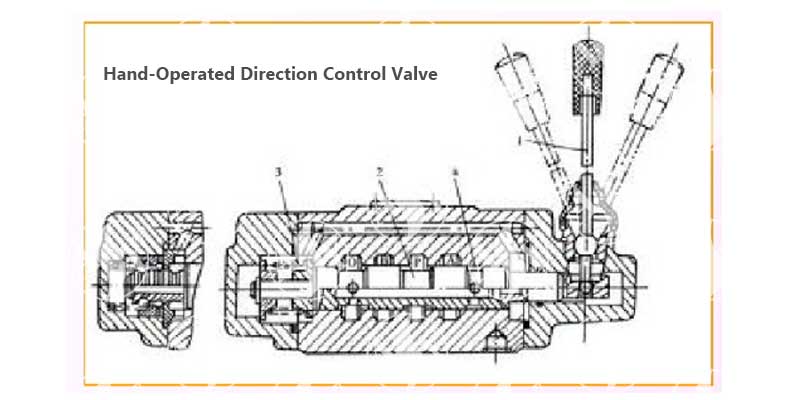

Hand-Operated Direction Control Valve

Hand-operated directional control valve is a common directional valve with multidirectional and adjustable path. Hand-operated directional control valve is easy to use and timely change the direction of flow. It mostly applies for some places that have low flow and long intermittent time.

Above all else, directional control valve have many other way to classify.

KaiDi is a Chinese supplier of solenoid for solenoid operated directional control valve. We specialize in manufacturing AC and DC hydraulic solenoids, such as hydraulic solenoid for Rexroth, Yuken, Vickers directional control valve; proportional solenoid, explosion-proof solenoid and displacement sensor. We also provide customization service by customers’ requirement. Based on 70 years’ experience in hydraulic solenoid processing and technology introduced from Bosch Company in German, we can promise one-year warranty.