In the following articles, we will discuss the design features of hydraulic solenoid. As a main actuator for hydraulic valve and hydraulic pumps, hydraulic solenoid is a basic electrical component which has been mass supplied in hydraulic industry.

What is Hydraulic Solenoid

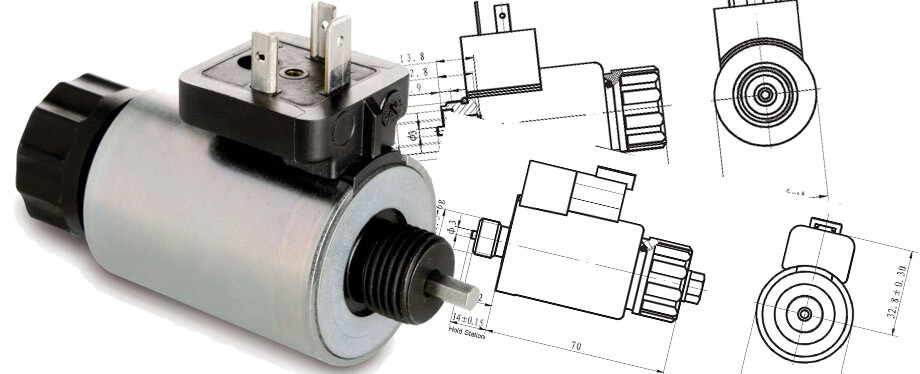

Hydraulic solenoid is a special type of electromagnetic solenoid which has been mainly used for hydraulic valves and hydraulic pumps. The function of hydraulic solenoid is similar to common electromagnetic solenoid. There is a solenoid coil winding around a metal tube. After electrified, there is a magnetic field has been created, the magnetic field creates magnetic force and acts upon the solenoid armature to make the plunger re-position.

Hydraulic solenoid is used to control the flow, pressure, and directions of hydraulic fluids. There are different types of hydraulic solenoid, on-off solenoid for directional valves, proportional solenoid for proportional valves, servo solenoid for servo valves. No matter which types of hydraulic solenoids, it can realize the pull and push functions.

Normally, hydraulic solenoid is used as the control element of hydraulic valves, but it can also be used on hydraulic pumps. Hydraulic pump is also a type of equipment that can convert mechanical energy into hydraulic energy. If we use a hydraulic solenoid on hydraulic pumps, it can help control the output volume of hydraulic fluids. Hydraulic solenoid is normally applied to variable displacement axial piston pumps which control the hydraulic fluid by pistons. The hydraulic solenoid for hydraulic pumps controls the swashplate. This swashplate is used to position the pistons of hydraulic pumps.

Hydraulic Solenoid Design

Hydraulic solenoid can be sold both integrated and separately. A complete hydraulic solenoid assembly includes a coated solenoid coil, and a solenoid tube assembly. When the hydraulic valve manufacturers place an order, they can choose solenoid coil only, solenoid tube only, or a whole hydraulic solenoid package.

Hydraulic Solenoid Coil Design

One of the most important features of hydraulic solenoid coil is replaceable. The coil and tube of hydraulic solenoid are separate. As we all know, the copper wire of solenoid coil can be burnt out, if the solenoid coil and tube are non-removable, we must replace the whole solenoid assembly when the solenoid coil burnt out. But with the replaceable design of solenoid coil, when something goes wrong of the coils, we can only change solenoid coil.

Typically, there are three types of hydraulic solenoid coils, the stamped type, rolled can type, and cylindrical can type. The stamped type hydraulic solenoid coil is the cheapest hydraulic solenoid coil, but at the same time, it also maintains the lower magnetic performance. The cylindrical type hydraulic solenoid coil has better coating construction, with the coil has been coated, so that it has better environmental protection performance and magnetic performance. Last but not least, the rolled can type hydraulic solenoid coil holds the best coating performance, with both the coil and the can are coated. Rolled can type hydraulic solenoid coil can also provide better magnetic performance and environmental protection performance than stamped type solenoid coil. Hydraulic valve manufacturers can purchase any types of hydraulic solenoids to fit your own hydraulic valve design.

Hydraulic Solenoid Tube Design

There are different designs of hydraulic solenoid tubes, such as 3 piece type, and infill braze type. 3 piece type solenoid tubes are more suitable for the on-off solenoid. The design structure of 3 piece type hydraulic solenoid tube is consists of two magnetic end and a non-magnetic tube. In this case, 3 piece type solenoid tube saves the cost, but if you plan to use it to make proportional solenoid, it must go through much more complicated processes to maintain the proportional functions. Therefore, before you purchase hydraulic solenoid tubes, to have a better communication with the hydraulic solenoid manufacturers will definitely help you get the most suitable solenoid tubes for your hydraulic valves.

Unlike the 3 piece type solenoid tubes, infill braze type hydraulic solenoid tube is more suitable for proportional solenoids. Infill braze type solenoid tube is an integrated non-magnetic metal which can help maintain the precise performance and control of hydraulic proportional solenoid. As you can see, a single piece design solenoid tube can highly guarantee the alignment and precise control of the plunger all by itself.

Except for the above solenoid types, there are also other hydraulic solenoid types, such as the electrical connector type hydraulic solenoids. As a leading hydraulic solenoid manufacturer in China, Kaidi Electromagnetic is a reliable hydraulic solenoid supplier of many top hydraulic valve manufacturers in the world, such as Rexroth, Yuken, Vickers, Parker, etc. And we are able to provide the whole series of hydraulic solenoids with customized requirements. Contact Kaidi freely, and get your custom hydraulic solenoid design right now.