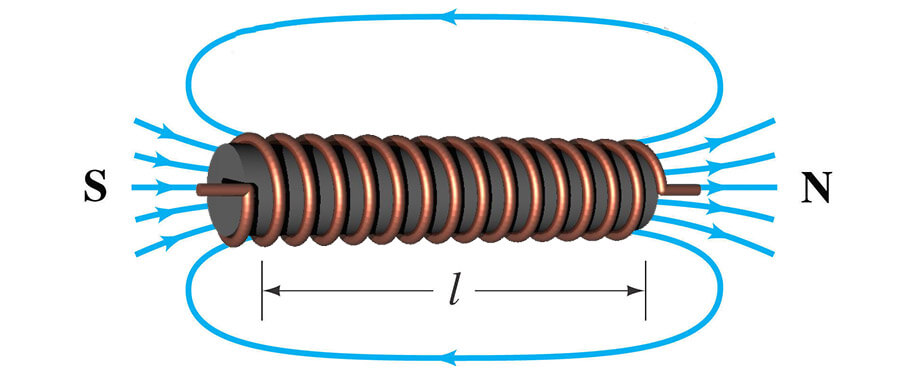

Solenoid is a device that uses electricity to generate a magnetic field. There are solenoid coils winding around the solenoid iron core, after electrifying solenoid coils, a small magnetic field has been created, and the iron core can be displaced. But when the electricity is cutting off, the solenoid iron core must be demagnetized at once.

Different Types of Solenoids

There are many different ways to classify solenoid types, as solenoids always show many different cross-reference features. In the following parts, we offer some different dimensions to classify different types of solenoids

According to different solenoid voltages, there are:

- DC solenoid

- AC solenoid

According to the different shapes of solenoids, there are:

- Frame type solenoid

- Tubular type solenoid

According to different performance of solenoids, there are:

- Keep solenoid

- Locking solenoid

- Flapper solenoid

- Massage solenoid

- Solenoid coil

According to different operating modes of solenoids, there are:

- Pull type solenoid

- Push type solenoid

- Holding solenoid

- Rotary solenoid

Except for the former solenoid types, there are also other ways to classify solenoids, such as the electrical solenoid, hydraulic solenoid, pneumatic solenoid, etc. When you are looking for buying solenoid, you must also pay attention to solenoid rated strokes, rated force, power frequency, etc.

Uses of Solenoids

In order to ensure the stable working ability and serve life of your solenoids (includes all the solenoid types we have mentioned before), there are several aspects we have to consider:

-

- The majority of solenoids uses DC voltage system, so if you require AC solenoid, please recheck the power system, or if your power system is alternating current, you can use full wave rectifier to convert the alternating current into direct current.

- The solenoid electricity connection rate is determined by the electricity connection time and the turn-off time. Except for the electricity connection rate of solenoid, we should also pay attention to the regulation about longest electricity connection time. These regulations prevent solenoid coil overheat problem, which can cause the fault actions of solenoid and the reduction of solenoid serve life. Therefore, we must use the solenoid under these regulations.

- The solenoid coil ampere turns is the product of the current value of solenoid coil and the number of turns of solenoid coils. Every solenoid coil electricity connection cycle provide parameter values, the mechanical output force of solenoids is in proportion to its winding number of the ampere.

- The complete performance of solenoid changes as the changes of solenoid coil temperatures. When the solenoid coil has been electrified, the temperature of solenoid coils keep increasing, so the solenoid coil resistance grows, too, which means the current in the solenoid coil circuit is low, and the winding number of ampere reduces, too. In this case, the mechanical power output of solenoid also grows lower. Normally, the solenoid coil data listed on solenoid catalogs are the solenoid coils data under 20℃.Table 1 Relations Among solenoid coil temperature, solenoid coil resistance and solenoid coil ampere turns.

Coil Temperature(℃) -40 -20 0 20 40 60 80 100 120 Coil Resistivity 0.764 0.843 0.921 1 1.079 1.157 1.236 1.314 1.393 Ampere Turns Ratio 1.309 1.186 1.086 1 0.927 0.864 0.809 0.761 0.718 - In order to control the temperature of solenoids, and make solenoids can be well operated under large ampere-turns, some solenoid manufacturers may stick a cooling fin on the solenoid.

- The relations between solenoid electricity connection rate and ampere-turns are placed below:Table 2 Relations Between Solenoid Electricity Connection Rate & Ampere Turns

Electricity Connection Rate 100% 50% 25% 10% Ampere Turns 1 2-2 2 10-2 Voltage 1 2-2 2 10-2 Power 1 2 4 10

Solenoid Applications

Solenoid holds a significant position in the industrial market, it is a basic actuator device, which is well known as “the king of electrical appliances”. As the development and competition of magnet device and iron removing device market grow heavily, both the quality requirements and productivity requirements of solenoid products are growing quickly.

There are many different types of solenoids has been widely used in industrial machinery manufacturing, such as lifting solenoid, brake solenoid, traction solenoid, pull-push solenoid, frame type solenoid, tubular solenoid, rotary solenoid, keep solenoid, holding solenoid, solenoid for DC wet valves, solenoid for AC wet valves, embroidery machine solenoid, electro-permanent chuck, automobile solenoid, hydraulic solenoid, pneumatic solenoid, etc.

Solenoids have been widely applied in many different industries, such as aerospace industry, mechanical industry, metallurgical industry, mining industry, ship-building industry, electronics power industry, coal industry, electric tool industry, transportation industry, lifting and transshipment industry, and the manufacturers, wholesalers of household appliance, electrical motor, door lock, textile machinery, game machine, medical equipment, gym equipment, office facilities, vending machine, building materials, chemical engineering, plastic, glasses, cement, paper making, food, fodder, water treatment, etc.